- HOME

- CSR Activities

- Environmental Report

- Efforts to Reduce Our Environmental Footprint

Efforts to Reduce Our Environmental Footprint

Environmental Impact of Business Activities and Environmental Initiatives

TS TECH identifies and strives to reduce the environmental impact of its business activities in each region of the globe.

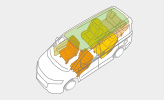

Development-Focused Measures

The TS TECH Group understands that reducing the weight of our products is one of the most effective ways in which we can reduce our impact on the environment. For example, our seat frames account for a large portion of the weight of our products, so we strive to apply a variety of weight-reducing technologies wherever possible, while further improving safety and comfort in line with evolving specification needs. The next-generation seat frame installed in the 2020 Honda Fit is about 28% lighter than our previous core frame. We accomplished this by using more ultra-high tensile strength steel and thin-plate welding technology. It is now being used in many automobile models worldwide. In addition to reviewing the use of aluminum and other materials, we are also focusing our efforts on technology that fuses different materials. Using the optimal designs for these materials, we will cut out even a single extra gram to develop frames that are the lightest in the world.

In addition to weight-reducing technologies, we are focusing on reducing CO2 contained in our products through technologies utilizing CNF1 and other plant-derived biomass materials. Compared to conventional door trims made from petroleum-derived materials, we have succeeded in reducing the amount of CO2 contained in these products by 60% by using plant-derived biomass materials (for resin/synthetic leather coverings), and we are continuing our research with the goal of applying this technology to mass-produced products.

Moreover, with the shift to electric vehicles (EVs) in mind, we are pursuing research and development that will contribute to carbon neutrality from various angles, such as the development of an Electronic Control Unit (ECU) for seat heaters that efficiently heat seats with low power consumption and an energy-saving air-conditioned seat, thereby contributing to improvements in electricity costs (fuel efficiency).

- *CNF: Cellulose nanofiber

Evolution of parts using ultra-high tensile strength steel (shown in blue)

Production-Focused Measures

With a policy to “build production plants that are sincerely welcomed by the local community,” our Manufacturing Division, which oversees our production plants, aims to contribute to a recycling-oriented society and promotes efforts to build “people-friendly, environment-friendly production plants.” Through the use of Japan’s traditional karakuri mechanisms, we have been able to simultaneously save energy, reduce workloads, and improve production efficiency through the promotion of a plant-wide framework that aims to automate work without consuming energy.

The karakuri competition we hold annually welcomed the involvement of domestic affiliates in fiscal 2022, and we will seek to further invigorate related activities. The top three entries in the competition are slated for inclusion in the Karakuri Kaizen Exhibition* organized by the Japan Institute of Plant Maintenance. We are committed to motivating our employees and incorporating other companies’ ideas for improvement in our work to accelerate the creation of energysaving, low-cost processes.

We also plan to hold a cross-departmental Group-wide meeting in fiscal 2023 to share successful cases of energysaving efforts made in the manufacturing domain. By encouraging horizontal deployment of such energy-saving examples, as well as working to standardize our production equipment worldwide, we will undertake the process of creating simple, slim, compact processes with low energy consumption at all our production sites.

- * The Karakuri Kaizen Exhibition is held every year in Japan to showcase improvements using karakuri mechanisms.

Karakuri activities at the Saitama Plant

Purchasing-Focused Measures

Considering the impact of energy consumption throughout the supply chain on the global environment, we are working to reduce our environmental footprint, not only within the Group but throughout the supply chain, with cooperation with from our suppliers. In particular, to help build a decarbonized society, it is essential that we know not just the greenhouse gas (GHG) emissions from the Group’s own business activities but also the emissions across the entire supply chain (Scope 3), and work to reduce them.

The TS TECH Group has formulated the TS TECH Supplier Sustainability Guidelines to share its approach to sustainability with its suppliers and promote it together. We ask our suppliers, including overseas suppliers, to comply with the guidelines and work with us to reduce our environmental impact.

Going forward, we will continue working to take stock of our GHG emissions throughout the supply chain and to reduce these emissions from a variety of angles.

Installing Environmentally Friendly Equipment

The TS TECH Group has installed a variety of equipment to reduce its environmental impact, including energy-saving equipment and solar power generating equipment that produces renewable energy.

In Japan, following achievement of a Nearly ZEB* (Zero Energy Building) rating with our new Head Office building, which we completed in conjunction with the previous Medium-Term Management Plan, we carried out factory reconstruction work in the Hamamatsu district. We installed environmentally friendly equipment including a rainwater recycling system to reduce our groundwater extraction and CO2 emissions. In addition, we are actively working to curb distribution loss by consolidating functions including external warehousing at the Hamamatsu Plant in order to reorganize production.

Overseas, TS TECH (THAILAND) CO., LTD. completed the Group’s largest installation of solar panels in fiscal 2021. The 2,600 solar panels made it possible to supply approximately 15% of the electricity consumed at the production site using solar power, thereby helping to reduce CO2 emissions. In addition, at TS TECH INDIANA, LLC (U.S.), where an expansion project was completed in June 2022, a new solar power generation system with over 4,000 solar panels and electricity storage capabilities has been installed. The company aims to become the first Group plant to cut its CO2 emissions virtually to zero by generating 50% of the electricity it consumes annually through the system while making active use of energy-saving equipment and renewable energy.

- *Nearly ZEB: A building that comes as close as possible to ZEB by nearing zero annual primary energy consumption

Newly installed solar power generation system at TS TECH INDIANA, LLC

Implementing Third-Party Verification

In order to ensure the reliability environmental data disclosure, the Group has obtained third-party verification from SGS Japan Inc. Verification results for fiscal 2023 are as follows.

| Verification target | Verification range | Results |

|---|---|---|

| Scopes 1 and 2 (CO2 emissions from energy use) and energy consumption | 6 sites of the Organization, 5 domestic companies, 27 overseas companies | Scope1: 7,083 t-CO2 Scope2: 49,937 t-CO2 |

| Scope 3, Category 1 (CO2 emissions from purchased products and services) |

Products and services extracted from TS production control system | 2,330,480 t-CO2 |

| Water intake | 6 sites of the Organization, 5 domestic companies, 26 overseas companies | 422,134 m3 |

| Waste generated (including valuable waste) | 16,203 t |