- HOME

- CSR Activities

- ESG TOPICS

- Special Feature 1: Sixty Years of the TS TECH Group

Special Feature 1: Sixty Years of the TS TECH Group

-

1960

Established Tokyo Seat Co., Ltd.

Took over the motorcycle seat business from predecessor Teito Fuhaku Kogyo Corporation

-

1963

Began producing automobile seats

From Producing Work Uniforms to Manufacturing Seats for Motorcycles and Automobiles

TS TECH’s predecessor, Teito Fuhaku Kogyo Corporation, manufactured work uniforms for Honda, who recognized the quality of our sewing technology and asked us to begin manufacturing motorcycle seats. Honda’s Super Cub scooter became a runaway hit and our production system expanded. We then began to manufacture lightweight seats for racing motorcycles, developing technologies early on to make seats lighter.

We later made seats for the Honda T360 pickup truck, which marked the start of TS TECH’s full-edged manufacture of seats for automobiles. From then on, the scale of our operations grew steadily.

Honda T360 seat

Seat for the original Honda Super Cub -

1970

-

1977

Expanded operations to North America

Early Establishment of a Manufacturing Base in North America

TS TECH first expanded its business outside of Japan in 1977, setting up a production subsidiary in Nebraska, U.S.A. to manufacture motorcycle seats locally for Kawasaki.

We later began production for Honda. A series of orders for automobile seats and leisure vehicle seats came in from American automakers, and the scale of local production was expanded. Today, the Group has production centers in Japan, the Americas, Europe, China, and other parts of Asia.

Assuring Quality

The seats for the original Honda Civic could be considered the starting point for TS TECH’s manufacture of automobile seats. When the model was launched, however, there were frequent issues involving seam tears in the covering and bent seat frames when used by people with larger body types. The system we established at that time to facilitate the immediate sharing of quality issues among departments and quick improvements is still in place today. We have turned this rough start into a legacy of a strong commitment to the perfection of quality.

Seat for the original Honda Civic

Launched 1972 -

1980

-

1990

-

1994

Expanded operations to Asia

-

1996

Expanded operations to South America

-

1997

Changed company name to TS TECH Co., Ltd.

-

1999

Expanded operations to Europe

Seat Arrangements Created Using Structural Design Technology

The 1990s saw a minivan boom. The interior was seen as a space to enjoy spending one’s time, generating demand for more comfortable seats. We then began a multi-pronged pursuit of comfort. One result of this pursuit was seat arrangement technology. We employed structural design technologies and a wealth of expertise to develop arrangements with various kinds of usability. TS TECH’s designs have earned a solid reputation among European automakers, who have long been leaders in the industry.

1996 Honda Step WGN swivel seats in face-to-face modeThe Relentless Quest for Weight Reduction: The Honda (Acura) NSX Aluminum Seat Frame

Honda’s top-of-the-line sports car, the (Acura) NSX, debuted in 1990. Making the car lighter was essential to achieving its phenomenal performance. We worked to develop a seat frame that only used aluminum instead of steel, the conventional material used for seats. We experimented with processing methods, rustproofing technologies, and more. Our wealth of technical expertise resulted in seats that greatly reduced the weight of the vehicle. The same technology was utilized for the newest NSX seats to develop a frame that blends aluminum with cutting-edge materials.

Honda (Acura) NSX seatPursuing Comfort

TS TECH continues to pursue comfortable seats that prevent fatigue by translating subjective judgments of comfort and fatigue, which vary by person, into quantifiable figures and conducting repeated research based on ergonomics. This approach is reflected in our unique theory of a comfortable posture.

Honda Odyssey Seat

Launched 2013The seat bottom tilts upward as the backrest is lowered to close in on the perfect posture for maximum comfort.

Honda Civic Seat

Launched 1995The first use of a mechanism to adjust seat height. This seat made it possible for smaller drivers to adjust to a more comfortable driving position.

-

2000

-

2001

Expanded operations to China

-

2007

Stock listed on the First Section of the Tokyo Stock Exchange

Aiming for Incomparable Quality and Achieving World-Class Quality

In order to compete alongside the world’s mega-suppliers, in the early 2000s, TS TECH first set its goal of achieving world-class quality. Under the slogan at the time, “Incomparable Quality,” we set out to not only improve production efficiency and quality through the installation of facilities such as jig lines but also to change people’s way of thinking about manufacturing. More recently, TS TECH has been a highly ranked supplier by vehicle size class in a seat quality and satisfaction survey conducted by an American research firm.

Safety Evaluation Technology Obtained through High-Performance Dynamic Sled Testing

In 2004, TS TECH introduced a new cutting-edge dynamic sled testing facility to reliably reproduce car crash impacts. The facility was the first of its kind in Japan. Over 1,000 tests are conducted annually, and the safety assessment technologies have led to TS TECH’s seats receiving top-class safety assessments from vehicle safety assessment organizations around the world.

Establishing a Strong Profit Structure

As business has expanded, we have been severely impacted by changes in the external environment, including a global financial crisis and natural disasters in different countries.

TS TECH has streamlined development and manufacturing through production line automation and other technologies. This has enabled our company to withstand external changes, laying the foundation for the current highly profitable structure of the TS TECH Group.

Automated welding equipment -

2010

TS TECH’s 50th anniversary

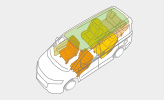

More Electrical Devices for More Comfortable, Safer Seats

Seats used to be simple, consisting mainly of a frame and cushion with leather covering. They have since evolved, and today many electrical devices are built into seats to add greater safety, comfort, and appeal. TS TECH has a department dedicated to the research and development of electrical devices. The department is a self-contained entity, handling everything from proposals of new features to control settings and system verification.

Electrical devices

(Shown in blue)Za Lab: A Research Group That Studies the Philosophy and Science of Seating

Za Lab was launched in 2012 with young employees selected from various departments to come together and research seating.

The interaction between different occupations generated many new, outside-the-box ideas. Za Lab continues to routinely conduct research in collaboration with the New Product Development Department to commercialize their ideas, a few of which have been shown at events such as the Tokyo Motor Show as prototypes. These and other ideas that have emerged from Za Lab will lead to future technologies.

Creating New Value

As the automotive industry enters a period of major transformation, the functions and value demanded of automobiles are also undergoing great change.

Even in the face of significant change, we aim to continue delivering attractive products that always exceed customers’ expectations. TS TECH is working to create new value with an eye to the future through our “Project to Create Exciting, Attractive Products,” which transcends the boundaries of the automotive industry.

A combination of sensing technology and the IoT Aisareru Seat -

2020

TS TECH’s 60th anniversary